滾(gun)筒(tong)輸(shu)送機,輥(gun)道(dao)輸送機,滾筒輸送(song)流水線的(de)構造(zao)原理:

Construction principle of roller conveyor:

滾筒輸送機,輥道輸送機,滾筒輸送流(liu)水線結構(gou)形(xing)式有:按(an)驅動方(fang)式(shi)可(ke)分(fen)為(wei)滾筒線和無(wu)動力滾筒線,按布(bu)置形式可分為水(shui)平輸送滾筒線(xian)、傾斜(xie)輸送滾筒線和轉(zhuan)彎滾筒線。

The structure forms are: according to the driving mode, it can be divided into roller line and unpowered roller line. According to the layout form, it can be divided into horizontal conveyor roller line, inclined conveyor roller line and turning roller line.

滾筒輸送機,輥道輸送機,滾筒輸送流水線標準規格:滾筒線內寬度為200、300、400、500、600、700、800、1000、1200mm等。

Standard specification: the inner width of roller line is 200, 300, 400, 500, 600, 700, 800, 1000, 1200mm, etc.

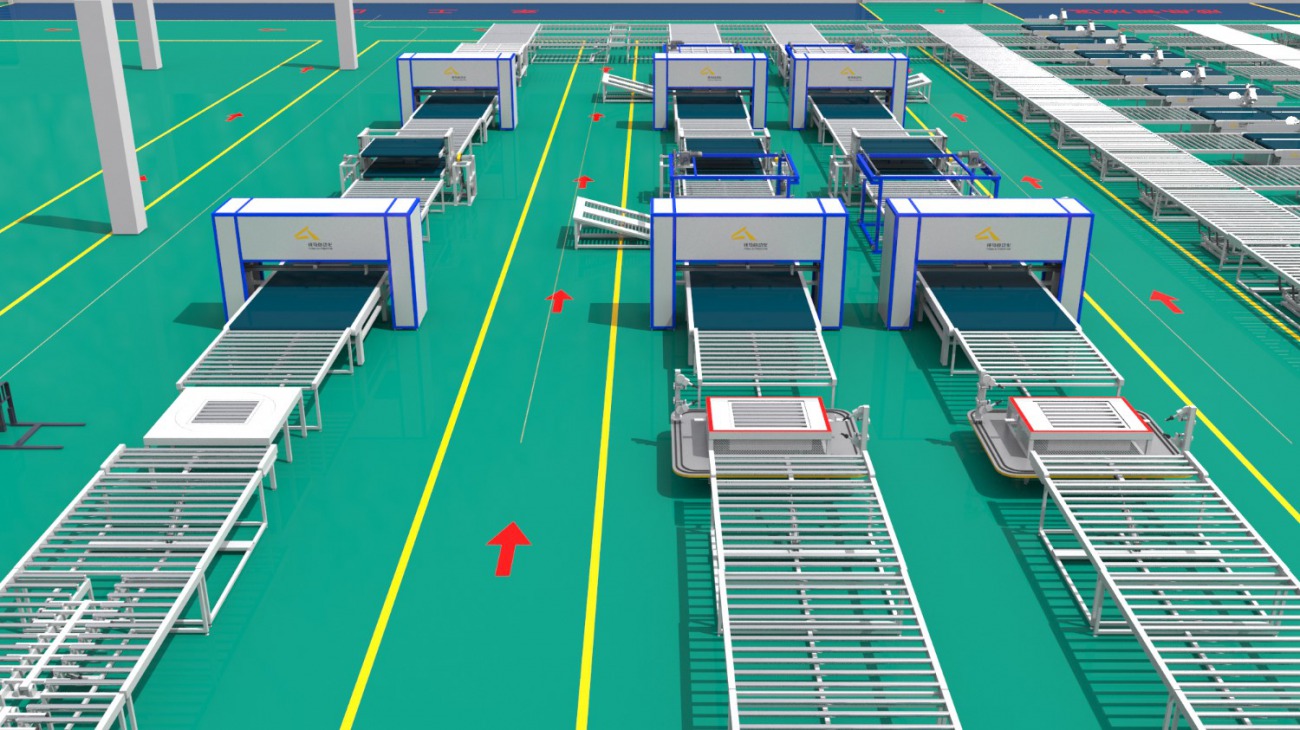

滾筒輸送機,輥道輸送機,滾筒輸送流水線設(she)備(bei)特點(dian):物(wu)流滾筒線之(zhi)間(jian)易(yi)於銜接過濾,可用多條滾筒線及其它輸送設備或專機組成(cheng)複雜(za)的物流輸送係統,完(wan)成多(duo)方麵的工(gong)藝需要。可采用(yong)積放(fang)滾筒實(shi)現(xian)物料的堆(dui)積(ji)輸送,物流滾筒輸送機結構簡單(dan),可靠(kao)性高(gao),使(shi)用維護方便。

Equipment features: it is easy to connect and filter the logistics roller lines. Multiple roller lines and other conveying equipment or special machines can be used to form a complex logistics conveying system to fulfill various process needs. The stacking roller can be used to realize the stacking and conveying of materials. The logistics roller conveyor has simple structure, high reliability and convenient use and maintenance.

1,無動(dong)力滾筒輸送機

1. Unpowered roller conveyor

無動力滾筒輸送機是最(zui)通(tong)用的一種(zhong)物流輸送機械(xie),是最經濟(ji)、最簡(jian)單的輸送設備,依靠外力來(lai)達到(dao)輸送物體的要求。

The unpowered roller conveyor is the most general logistics conveying machinery, the most economical and simple conveying equipment. It relies on external force to meet the requirements of conveying objects.

滾筒輸送機,輥道輸送機,滾筒輸送流水線滾筒材料分為:PVC、碳(tan)鋼(gang)鍍(du)鋅(xin)、不(bu)鏽鋼、鍍鎳等材質的多種筒徑與長度(du)的各(ge)式滾筒滿足不同(tong)寬(kuan)度、長(zhang)度的輸送設備。

Drum material is divided into: PVC, carbon steel galvanized, stainless steel, nickel plated and other materials of various drum diameter and length to meet different width and length of the conveyor.

機架型(xing)材分為:碳鋼噴(pen)漆、碳鋼噴塑(su)、不鏽(xiu)鋼型材、鋁合(he)金型材(cai)。

Frame profiles are divided into: carbon steel painting, carbon steel plastic spraying, stainless steel profiles, aluminum alloy profiles.

2,直(zhi)線滾筒輸送機

2. Linear roller conveyor

滾筒輸送機,輥道輸送機,滾筒輸送流水線是常(chang)見的連(lian)續(xu)輸送設備,由(you)於其在(zai)輸送成件物品時所具(ju)有(you)的明顯(xian)優點,使它不僅可以連接生產工藝(yi)過程,而且(qie)可以(yi)直接(jie)參(can)與生產工藝過程(cheng),因而在電子(zi)、電(dian)器(qi)、醫(yi)藥、化工、五金(jin)、食品、飲(yin)料(liao)、紡(fang)織(zhi)、建(jian)材業(ye)和(he)各類(lei)物流輸送中,尤其是(shi)在各種加(jia)工、裝(zhuang)配(pei)、包裝、儲(chu)藏(cang)等流水線中得(de)到了(le)廣(guang)泛的應用。

Roller conveyor line is a common continuous conveying equipment. Because of its obvious advantages in conveying finished products, it can not only connect the production process, but also directly participate in the production process. Therefore, in the electronic, electrical, pharmaceutical, chemical, hardware, food, beverage, textile, building materials industry and all kinds of logistics transportation, especially in various processing and assembly , packaging, storage and other assembly lines have been widely used.

3,伸(shen)縮式滾筒輸送機

3. Retractable roller conveyor

伸縮式輸送機設計(ji)先進(jin),使用靈活,因而受(shou)到用戶(hu)的歡迎,是輕(qing)型輸送設備中(zhong)佼佼(jiao)者.它的每單元可由8隻(zhi)輥子組(zu)成,每一個單元都(dou)可獨立使用,也(ye)可多個(ge)單元(yuan)聯接使用,安(an)裝方便(bian)。 輥道輸送機可伸縮自(zi)如(ru),一個單元最長與(yu)最短狀態之比可以達(da)到3倍,該輥道輸送機可靈(ling)活(huo)改變(bian)輸送方向,更大時可以大於180℃ 。

With advanced design and flexible use, the retractable conveyor is welcomed by users. It is a leader in light conveying equipment. Each unit of the retractable conveyor can be composed of 8 rollers, each unit can be used independently, or multiple units can be connected for use, and the installation is convenient. The roller conveyor can stretch freely, and the ratio of the longest and shortest state of a unit can reach 3 times. The roller conveyor can flexibly change the conveying direction, which can be greater than 180 ℃ at the maximum.

4,精密側摩擦式積放滾筒輸送機

4. Precision side friction roller conveyor

其結構主要(yao)包括驅動電機、套(tao)筒滾子鏈(lian)條、精密(mi)積放滾筒、鋁(lv)合金整(zheng)體旁(pang)板(ban)、機架(jia),其(qi)中驅(qu)動電機、套筒滾子鏈、傳動鏈輪(lun)、精密(mi)積放滾筒依次相接,精密(mi)積放滾筒通過軸承安裝在鋁合金主旁板上,鋁合金主旁板安裝在機架(jia)上。本(ben)實用新型的優(you)點:與傳(chuan)統(tong)的積放滾筒輸送機相比,本發明(ming)具有加工精度高,其運(yun)行(xing)徑向跳動小,積放力矩(ju)可調(diao),整機結構緊(jin)湊,日常運行能(neng)耗(hao)較小,運行噪(zao)音較小,日常維(wei)修保(bao)養工作量小,在輸送鋁合金缸(gang)體零部(bu)件(jian)時不會(hui)碰(peng)傷(shang)鋁合金缸體(ti)的精密加工麵(mian),從(cong)而(er)能很好地適應(ying)鋁合金缸體的機加工線的工件輸送需(xu)求。

Its structure mainly includes driving motor, sleeve roller chain, precision stacking roller, aluminum alloy integral side plate and frame, wherein the driving motor, sleeve roller chain, driving sprocket and precision stacking roller are connected in turn, the precision stacking roller is installed on the aluminum alloy main side plate through the bearing, and the aluminum alloy main side plate is installed on the frame. The advantages of the utility model: compared with the traditional stacking roller conveyor, the invention has the advantages of high processing accuracy, small radial run out, adjustable stacking torque, compact structure, small energy consumption in daily operation, small operation noise, small daily maintenance workload, and no damage to the precision machining surface of the aluminum alloy cylinder when transporting the parts of the aluminum alloy cylinder, so it can It can meet the needs of workpiece transportation in the machining line of aluminum alloy cylinder.